Sustainable Food Packaging

Switch to Environmentally Responsible, Biodegradable Packaging Solutions

80% of total plastic in the world ends up in landfills, which are full of active microbes that eat everything, except common plastic. If these microbes could eat plastic, they could have a good food and energy source.

Progressive Packaging has partnered with ZUBIOX products, who have created a product that works, looks and feels like traditional plastic packaging, but are able to absorb moisture in landfills and allow these crucial microbes to enter these new plastics. These microbes attract more microbes, multiplying the effect and allow these products to naturally decompose in to organic material.

Switching to sustainable food packaging has never been an easier decision! These new packaging products perform just as well as traditional plastic products, look and feel the same, but are safe for the environment.

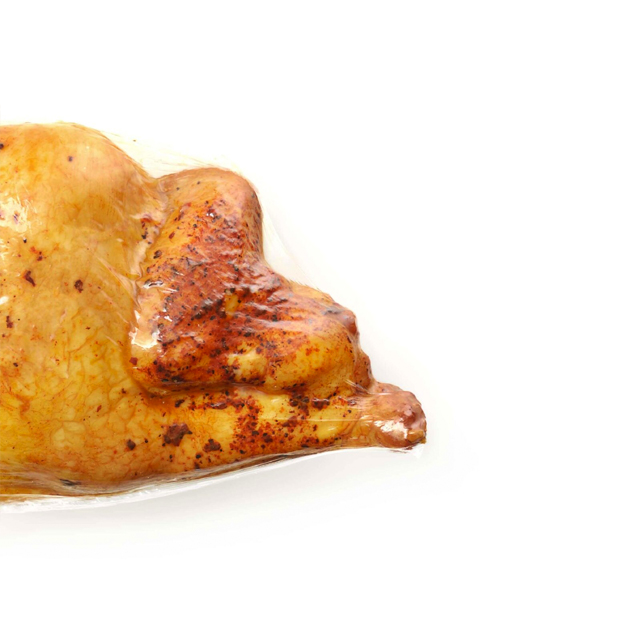

Thermo Shrinkable Bag

Thermo shrinkable bag with a medium barrier, for vacuum packaging with high shrinkage percentage (40%). It is manufactured using a 7 layer co-extrusion process and it is recommended for applications such as cheese packaging, poultry, raw or fresh fish.

High Barrier – High Shrinkage Film

Vacuum bag with 7 co-extruded layers with a high shrinkage percentage and a high barrier. Specially created for products with bone, guaranteeing high resistance to puncture.

Medium Barrier – Cook-In Bag

Our Cook-In bag is a medium barrier to oxygen and water vapor Cook-In Bag. Can to be used as packaging material in the food industry and cook food. Polymers of the highest quality, approved to be in contact with food, are used for the manufacture of this Cook-In Bag.

Bone Guard Bag

Vacuum bag with 7 co-extruded layers with a high shrinkage percentage and a high barrier. Specially created for products with bone ensuring high resistance to puncture.

Liquid retention Technology for Trays

Introducing our award-winning padless tray technology, cleverly designed to remove the need for absorbent pads for fresh cuts of protein. The features in the base of the tray capture and retain liquid. It’s more sustainable because it’s easy to rinse and recycle without any mess. And a full range of standard sizes makes it easy and quick to make the switch.

- Next generation sustainable protein tray, improving recycling rates

- Can include kp Tray2Tray® content

- kp Tray2Tray® content contributes towards a closed loop

- Easy to rinse, recycle and repeat!*

Flexible Film Product

LINtop® PE HSF is a thin 25 μm, high barrier, tray lidding film that is abuse-resistant, anti-fog, leak-proof and printable. Ideal for retail ready modified atmosphere packaging formats. Tailor made shrink performance produces tight, wrinkle-free packs with outstanding clarity and consumer appeal. Ideal for manual and automatic lidding machines and other qualified Form Fill

and Seal machines.

- Low gauge film

- Available in longer rolls for less line downtime

- Reduced carbon footprint

- Limit food waste

Premium Base Rigid Film

Introducing our top of the range, sustainable PET base rigid film for form, fill and seal applications. kp MonoSeal™ is a

mono PET film that is fully recyclable, with the strongest sealing capability in the market and is 7% lighter than

multi-layer films. Perfect for fresh food applications, from protein and cheese to pasta.

- Fully recyclable*

- Mono PET material

- Downgauged 10% and longer

- rolls, requiring less energy input

- Reduction in sealing temperatures

- Lower carbon footprint